Last updated 24 November 2025

Seastreak is a ferry service between New Jersey and New York City, and entered service at the early 2000’s. The fast ferry was originally delivered with four diesel engines and four water jet drives.

Fuel cost has always been one of the most critical cost drivers in high-speed ferry operations. As fuel prices increased and environmental expectations tightened, Seastreak sought a more efficient propulsion concept. This search led them to the Servogear Ecoflow Propulsion System, which provided a step-change in efficiency.

This case study explains how the Seastreak Wall Street achieved:

-

32% lower fuel consumption

-

Over USD 500,000 in annual savings

-

50% lower CO₂ emissions per passenger

-

Higher top speed despite reduced installed power

Understanding Fast Ferry Operations

Before we dig into the details of how Seastreak reduced emissions and operational cost, let’s have a quick look at fast ferries.

Fast Ferries are vessels that transport passenger, and their income is generated from the passengers. A typical fast ferry has a high number of operational hours per year; approximately 5000 hours per year/12 hours per day.

Furthermore, these vessels tend to have multiple berths every single day. Consequently, the vessel requires good maneuverability to reduce the time during berths and must be efficient during high speeds.

The typical operational requirements of a fast ferry is:

- 4500 hours/year

- 32 knots

- 400 Passengers inc luggage and fuel

- Payload variation 50 tonnes

- Highspeed operation in schedule: 32 knots (80%)

- Harbour at slow speed (5-10 knots) (10%)

- Harbour, Manouvering: 15 berthings pr day (10%)

Because such a large share of operation occurs at top speed, even small improvements in propulsion efficiency can yield major reductions in OPEX and emissions.

Read more: Potential Fuel Saving in Converting from Water Jet to CPP

From KaMeWa Jet to Servogear Ecoflow Propulsion

Seastreaks goal was to improve emissions and reduce fuel use by 20% and obtain reduced carbon emissions due to reduced fuel consumption.

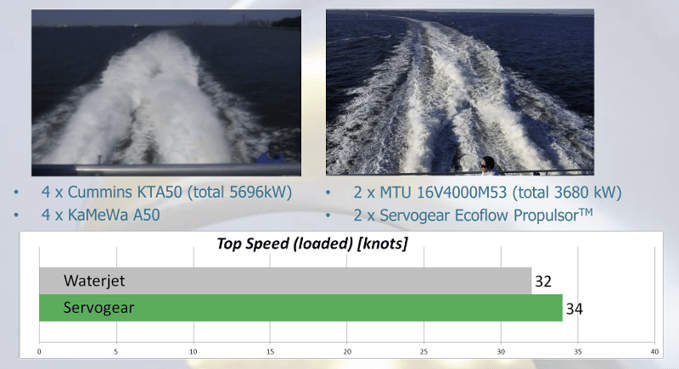

To achieve greater fuel efficiency for the Seastreak Wall Street vessel, Servogear did a retrofit and re-powering of the 43 m fast ferry from KaMeWa Jet to Servogear Ecoflow Propulsion (CPP systems). 4x Commins Diesel @ 5700 kW total was replaced with 2x MTU Diesel @ 3700 kW total.

As previously mentioned, it is common for 80% of the operational profile to happen at top speed. This is when the fuel consumption is at its peak. Hence, it is crucial for fast ferries to optimize this part of the operations as much as possible.

In fact, the fuel consumption for a fast ferry can be approximately 50% of the overall OPEX. Not surprisingly, you can thus easily achieve costs-savings of more than 30% through proper optimization.

By replacing and reducing the engines from 4 to 2 there are 2000 kW less engine power. Consequently, the reduction in operational cost is significant. In addition, the Servogear Ecoflow Propulsion system increases the full load speed from 32 to 34 knots.

As a result of these improvements, fuel consumption is down by 32% which constitutes 500 000 USD/y. CO2 emissions per passenger is halved.

Read more: How to Reduce the Operational Cost of your High-Speed Vessel

Why the Upgrade Worked

The major efficiency gains came from three factors:

1. Propeller Efficiency at High Speed

Ecoflow CPP systems maintain optimal pitch across the whole envelope, reducing slip and ensuring high thrust efficiency where fuel burn is highest.

2. Reduced Mechanical Losses

Switching from four engines and jets to two engines and CPP reduced mechanical complexity and parasitic losses.

3. Lower Hydrodynamic Resistance

The Servogear system is designed as a fully integrated propulsion package, tuned to hull shape, operating profile, and speed regime.

Conclusion

Seastreak wanted to lower carbon emissions, reduce fuel consumption and consequently their operational cost. By choosing the Servogear Ecoflow Propulsion system, they were able to reach these goals – and move towards a greener future.