Updated November 25 2025.

The maritime industry is rapidly evolving, driven by increasingly strict requirements for energy efficiency, emissions reduction and long-term operational sustainability. To meet both current and future regulations, operators and shipbuilders are turning to innovative vessel designs that combine high performance with advanced electrification and optimized hydrodynamics.

MS Medstraum is a pioneering result of this transition — the world’s first fully electric, zero-emission high-speed ferry. Developed through the EU-funded TrAM project, initiated by Maritime CleanTech and led by Kolumbus with support from Rogaland County Council, Medstraum won Ship of the Year 2022 and currently operates on routes in and around Stavanger, Norway.

This article provides an in-depth look at the vessel, with a focus on how the Servogear Ecoflow Propulsion System contributes to the future of green high-speed transport.

What Is a Typical Fast Ferry?

Fast ferries operate under demanding conditions, regardless of energy source:

- Around 5,000 operating hours per year

- Multiple daily berths, requiring excellent manoeuvrability

- Long periods spent at high speed

- Highly variable load conditions (full outbound, light on return)

Approximately 80% of a fast ferry’s operational profile occurs at top speed — the segment with the highest energy demand. Optimising this part of the profile is essential to reducing energy consumption and emissions.

Read more: The Seastreak 'Wall Street' Fast Ferry and How they Reduced Operational Cost and CO2 Emissions

The Groundbreaking Fast Ferry “Medstraum”

Objective & Aim

The TrAM project aimed to develop a zero-emission fast ferry using modular production methods. Key objectives included:

- Reducing production costs by 25%

- Reducing engineering costs by 70%

- Demonstrating a scalable model for electric high-speed vessels

Achievements

Medstraum marks a major technological breakthrough:

-

First electric vessel to exceed 23 knots, the threshold for high-speed classification

-

Achieves roughly 80% total propulsion system efficiency

-

Provides about 30% lower energy consumption than conventional alternatives

-

Cuts approximately 1,500 tonnes of CO₂ annually compared with fossil-fuel vessels

-

Carries 147 passengers across 12 daily stops, cruising at 23 knots

-

Operates 100% on battery power, with no fossil fuel backup

Read more: The most valuable energy is the one you do not use

The Path to Success: The Propulsion Concept

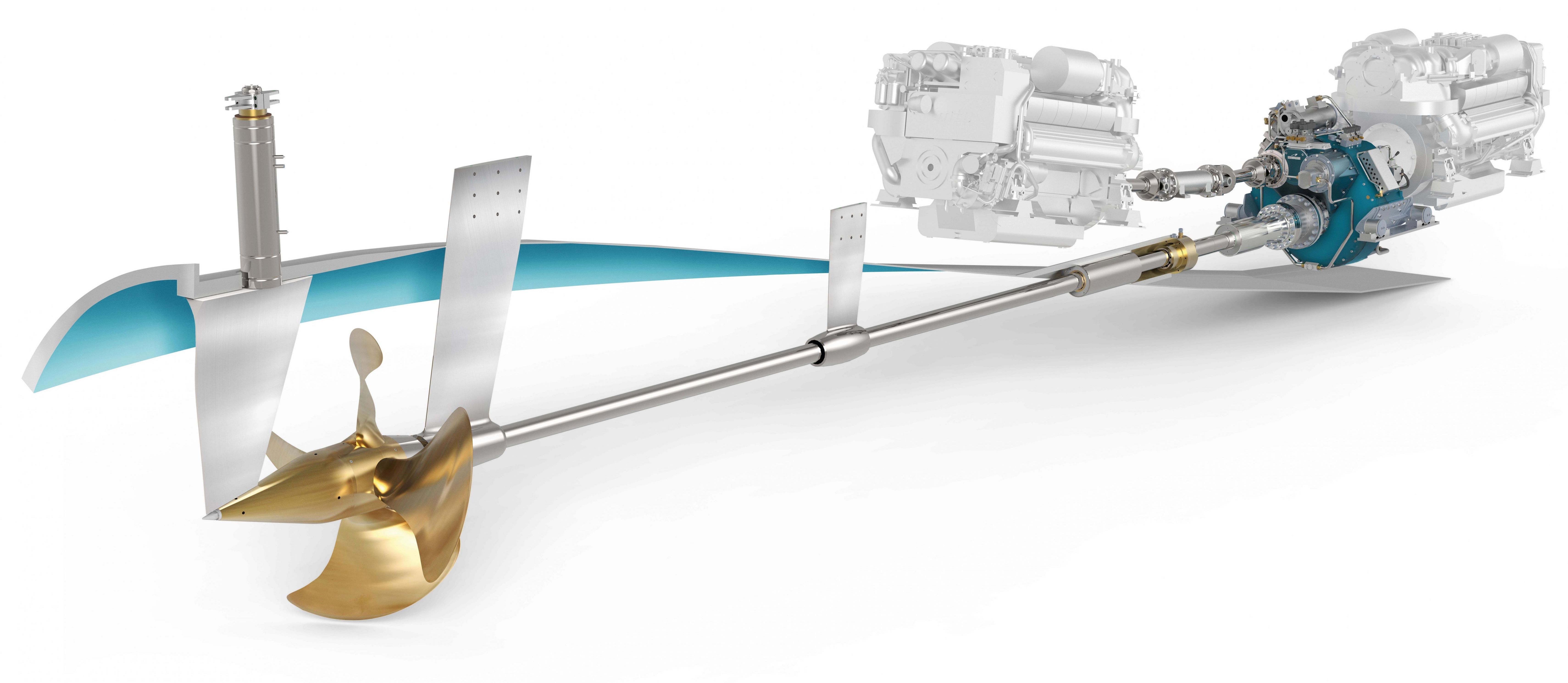

Medstraum is powered by the Servogear Ecoflow Propulsion System, which includes:

- HD 220 E gear

- Streamlined rudders

- Fully optimised shaft line

- Servogear Electric Flow Propeller

- Carbon fibre brackets and lightweight components

The system was fully customised to the vessel’s hull form, displacement and operational profile.

1. Reducing Weight

Reducing vessel weight is critical for lowering resistance and minimizing energy demand.

Medstraum achieved significant weight reduction through:

Material optimisation

- Extensive use of lightweight aluminium

- Detailed evaluations of which components could be downsized or placed onshore

- Compact and energy-efficient onboard systems

Carbon fibre brackets

One of the most innovative upgrades was the introduction of carbon fibre brackets, replacing traditional stainless steel or brass. This:

- Reduced total vessel weight by several hundred kilograms

- Contributed to a propulsion system that is 15% lighter than standard solutions

This is a practical example of how Servogear leverages advanced material technology to maximise hydrodynamic efficiency.

2. The Hull Design

Minimising resistance through optimal hull design is fundamental for high-speed electric vessels.

Extensive CFD-driven hull development

In collaboration with HSVA and universities in Scotland and Athens, more than:

- 2,000 hull variants were tested using Computational Fluid Dynamics (CFD)

- Fine hull lines and reduced wetted surface were achieved

- Appendages (rudders, brackets, shafts) were meticulously optimised

Strategic battery placement – above deck

Placing the battery packs above deck delivered several key benefits:

- Allowed the hull to be designed for hydrodynamic performance rather than battery volume

- Improved safety by reducing risk of seawater ingress

- Enhanced air cooling and ventilation

- Made batteries more accessible for inspection and maintenance

- Delivered better stability across load conditions

This design principle has since become a best practice in electric fast-ferry development.

3. Optimizing the Propulsion Line

An efficient propulsion line requires optimal interaction between gear, shaft, rudder, brackets and propeller.

Hydrodynamic improvements

- Carbon fibre brackets reduce turbulence and drag

- Streamlined rudder geometry improves steering efficiency

- Optimal placement ensures maximum thrust per kWh

Controllable Pitch Propeller (CPP)

The CPP system enables:

- Ideal engine loading under all conditions

- Energy savings in variable weather and load profiles

- Smooth and predictable harbour manoeuvring

- Reduced mechanical stress → lower maintenance costs

This adaptability is one of the main reasons why Medstraum achieves such high propulsion efficiency compared with waterjets or fixed-pitch propellers.

Read more: Why Twist Your Rudder

Conclusion

MS Medstraum demonstrates the potential of combining:

- Innovative hydrodynamic design

- Lightweight construction

- Fully electric high-speed propulsion

- A finely tuned CPP-based propulsion line

The vessel stands as a global reference for zero-emission fast ferry technology, proving that high performance and ultra-low energy consumption can go hand in hand.

Medstraum is not just a vessel — it is a blueprint for the future of green maritime transport.

Medstraum: Other Facts

Length: 30,4 meters

Beam: 9,0 meters

Built year: 2022

Gross tonnage: 225

Passengers: 147

Route Speed: 23 knots

Max Speed: 27 knots

Battery Capacity: 1524 kWh

Charge Capacity: 2,3 MW

Electric Engines: 2x Permanent Magnet Motors (550 kW)

Fresh Water Tank: 400 liters

Sewage tank: 1000 liters

Luggage: 20 Bicycles

Facilities: 3 toilets

Rescue Systems: 2x 150m Survitec open reversible rafts.

2x Servogear Gearbox

2x Servogear Controllable Pitch Propellors

2x Corvus Dolphin Power Lithium Battery Systems for propulsion and hotel load

Project Partners:

Kolumbus

Rogaland Fylkeskommune

Fjellstrand

Leirvik

Maritime Cleantechk

HSVA

Servogear

Wärtsilä

Hydro

University of Strathclyde

Fraunhofer

The National Technical University of Athens

Uber Boat

De Vlaamse Waterweg

![[Cover] EN Servogear Service Ecoflow Propulsor Leaflet](https://hubspot-no-cache-eu1-prod.s3.amazonaws.com/cta/default/26627183/interactive-100517025219.png)