Updated 27 November 2025.

In recent years, there has been a global movement towards zero-emission solutions. The maritime industry is no exception. We can only commend governments, environmental organisations, and businesses increasingly investing in sustainable technologies. This shift is not only driven by environmental concerns but also by the growing demand for cleaner alternatives in markets where maritime activities play a significant role.

Amid this transformative period, Rødne, one of Norway's leading sightseeing ferry operators, has commissioned a new hybrid fast ferry to meet demand for sustainable sightseeing tourism in the Bergen area. This cutting-edge hybrid vessel, scheduled for delivery in 2025, is part of the concerted effort to continue the introduction of eco-friendly alternatives on the Norwegian waterways.

In this article we will delve into the technical considerations and innovations of the yet unnamed hybrid vessel. We will turn our attention to the propulsion system designed and implemented by Servogear. We will henceforth refer to the unnamed vessel as «RygerX», following Rødne's naming conventions.

The Operational Profile of a Sightseeing Vessel

Understanding the operational profile is crucial when designing a modern low-emission vessel. For RygerX, it will consist of a high-speed transport stage to the designated area, Mostraumen. Once arrived, it will have a series of slow speed and loitering stages, during sightseeing in the serene natural environments, before a high-speed return.

With such a dynamic operational profile it is a delicate balancing game between effect and efficiency. The RygerX is also planned to be upgraded to fully electric once charging infrastructure has been constructed at its port. This further affects considerations and specifications of several key systems.

For efficient electric propulsion, you want a low RPM and a high propeller pitch pitch. A diesel engine can not be operated efficiently at such low RPMs, which must be calculated and designed around.

Ragnhild Opsahl Steigen, CTO at Rødne, had this to say about their considerations:

"We chose Servogear's CPP solution for our new vessel after considering several factors. Servogear offers the most energy-efficient solution in the market, and they have a deep understanding of our operational profile. Their commitment to service availability further strengthened our decision.

By working collaboratively and recognizing the value of joint efforts, we were able to customize solutions that seamlessly align with our operational needs."

- Ragnhild Opsahl Steigen, CTO at Rødne.

The Design

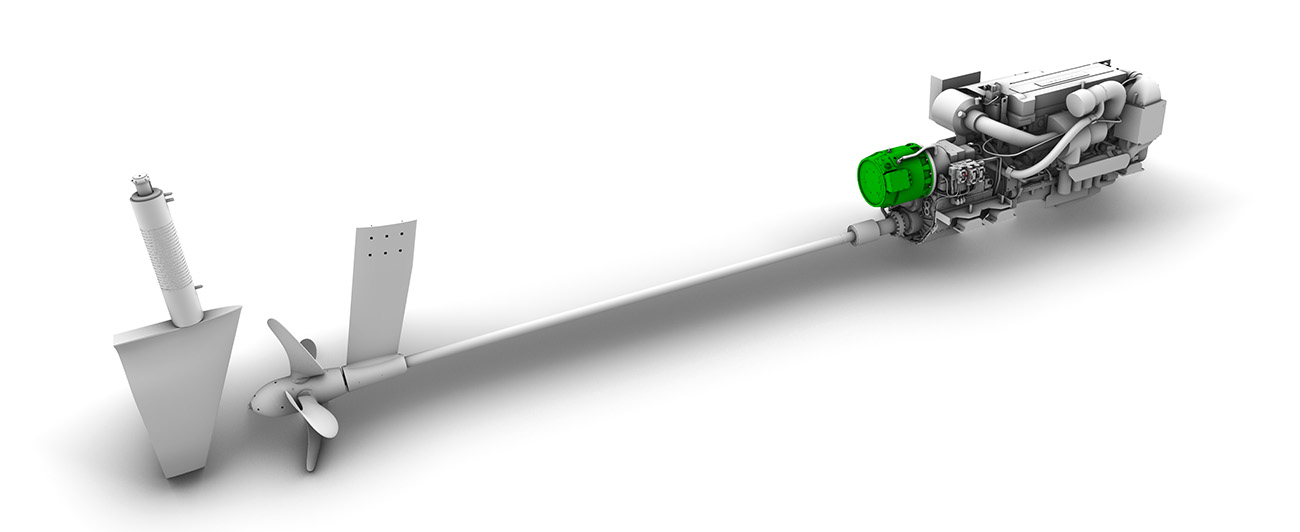

Crucial for an efficient vessel is the hull, and this is also where a lot of the design considerations originate. Propeller, brackets, rudder and propeller tunnel must compliment the hull-design. To make the vessel as energy efficient as possible, the propeller tunnel is designed/tailored for this specific hull. Upon launch the new vessel will be powered by 2 x Danfoss electric motors and 2 x Volvo Penta diesel engines, connected in parallel to a pair of Servogear CPP (controllable pitch propeller) propellers, through 2 x Servogear PTI gearboxes.

Prepared for an Electric Future

Since the new vessel is planned to be upgraded to fully electric in the future, there went a lot of effort into finding the optimal solution, achieving an optimal balance between high-speed efficiency and sightseeing capabilities. RygerX is different from many other sightseeing vessels since she is built under the HSC (High Speed Code) notation, meaning the speed is above 20 knots.

The design must also facilitate for making the upgrade a relatively easy process. Take out the diesel engine and fuel tank and put in more batteries and another electric motor. The new electric motor, which must match the RPMs and torque of the replaced diesel motor, but otherwise only need a compatible foundation constructed. The vessels should retain most of its other components, as well as classification and certifications.

This affects both considerations and specifications. For instance, a larger propeller could lead to a reduced need for battery capacity and weight. However, any such gain could be lost in the time and resources going into system redesign and replacing other components, like propeller shaft, tunnel as well as the gearbox and propeller brackets.

Read more: Efficient Propulsion in a Green Environment, What are the Options?

The Path to Success

There has been a close cooperation between the operator Rødne, Servogear and the designer/yard, Brødrene Aa. There it is always a lot of mutual respect and admiration in a partnership like this. However, nothing is ever taken for granted. As a major yard, Brødrene Aa has many suppliers, and there are other alternative propulsion systems.

However, the level of efficiency and low emissions that the Servogear solution provide is considered by many unparalleled. Such efficiency was a requirement from the forward-thinking operator, Rødne. Key here is addressing the challenges of simultaneously catering to sightseeing and high-speed requirements. While some may argue that these objectives are mutually exclusive, there is both data and examples proving you can have your cake and eat it too.

We should emphasise the importance of good communication between all central parties from the design stage and onwards in a project like this. A lot of work goes into calculations and design even before a contract is signed, guaranteeing that the client’s specifications are met.

"With Servogear, we're not just investing in cutting-edge technology, but we're forging a partnership that ensures our vessel's optimal performance, efficiency, and reliability throughout its operational life.

Our longstanding relationship with Servogear began in 1982, with the installation of the first Servogear propulsion system in our high-speed vessel Clipper, reflecting a commitment to excellence."

- Ragnhild Opsahl Steigen, CTO at Rødne.

The design process

Servogear receive the resistance curve/data as well as the general arrangement/line drawings of the hull. This becomes the foundation of the performance calculations and design of the propulsion system. Simulations and calculations, at various speeds, are conducted to optimize the efficiency of the system. A lot of emphasizes is put into the design of the engine room to find space and select the best layout of the power train.

The intended operational profile is then taken into the equation, completing the initial calculations. You now have the necessary data to start the engineering process.

Illustration - Credit: Brødrene Aa

Optimizing the propulsion line

There will always be some compromises, but with a CPP (Controllable Pitch Propeller), you have greater leeway in terms of efficiency and effect. CPP can in many ways be compared to an additional set of “drive-gears” for your vessel. A fixed propeller does not have this dynamic. Bad weather, strong winds, and currents with a fixed propeller, is a marine analogue for your car climbing a steep hill and only running in the 5th gear. It will be slow, and inefficient.

CPP is therefore crucial for a vessel seeking to optimize for efficiency across a dynamic operational profile. In RygerX´ case, the equation increases in complexity due to the planned upgrade of the vessel.

Read more: Why CPPs are the preferred choice for wind farm vessels

Summary

We hope this exploration has provided you with some insights to Rødne's new vessel and the design considerations of its hybrid propulsion system.

It is equally important to emphasise the good communication between the customer Rødne, the yard Brødrene Aa, and the suppliers of vessel's systems, even from an early design stage. Efficiency excellence and low emissions is only achievable when built from the ground up, which takes both commitment and dedication from multiple parties throughout the process.

We are looking forward seeing a christened RygerX on the water and in operation next year. We believe it will fulfil, if not exceed, both user's and the owner's expectations in terms of performance and efficiency. You should remain optimistic for the industry’s ability to drive innovation and bringing emissions and operational cost down.

![[Cover]-EN-Servogear-Concept-Brochure-Propulsion-Efficiency-Beyond-Belief](https://hubspot-no-cache-eu1-prod.s3.amazonaws.com/cta/default/26627183/interactive-96011088080.png)